Blog

January 25th, 2021

How to overcome the challenges in formulating mineral sunscreens and foundations

With an increased awareness of the dangers of overexposure to the sun and the need for use of sunscreens, the need for formulating more effective and safe sunscreens has been on the rise.

In the recent years sunscreens with added benefits have become popular. Anti-ageing sunscreens, foundations with high SPF values in addition to pre- and after- sun care products and self tanners. In this trend and due t the regulatory constraints in using chemical sunscreens, resulted in the use of mineral sunscreens, namely titanium dioxide (TiO2) and zinc oxide (ZnO). Despite an excellent safety profile, high SPF efficacy, broad spectrum protection and photostability, their application, however, grew slowly, mainly due to their poorly perceived aesthetics like skin feel and whitening. The “nano issue” speculating that nano particles pose a risk to penetrate through the skin and cause various hazards was another reason of their limit of use.

The recent advances in technology of Non-nano inorganic sunscreens have made them more attractive to both manufacturers and consumers which resulted in a better transparency on skin, higher efficacy in terms of SPF and UVA protection, better skin feel, and ease of use and compatibility with other ingredients.

Up until recently, to have a broad-spectrum product, there was a necessity for incorporation of TiO2 to contribute to the SPF number and ZnO seemed to be essential to make the formulations broad spectrum by covering the UVA spectrum.

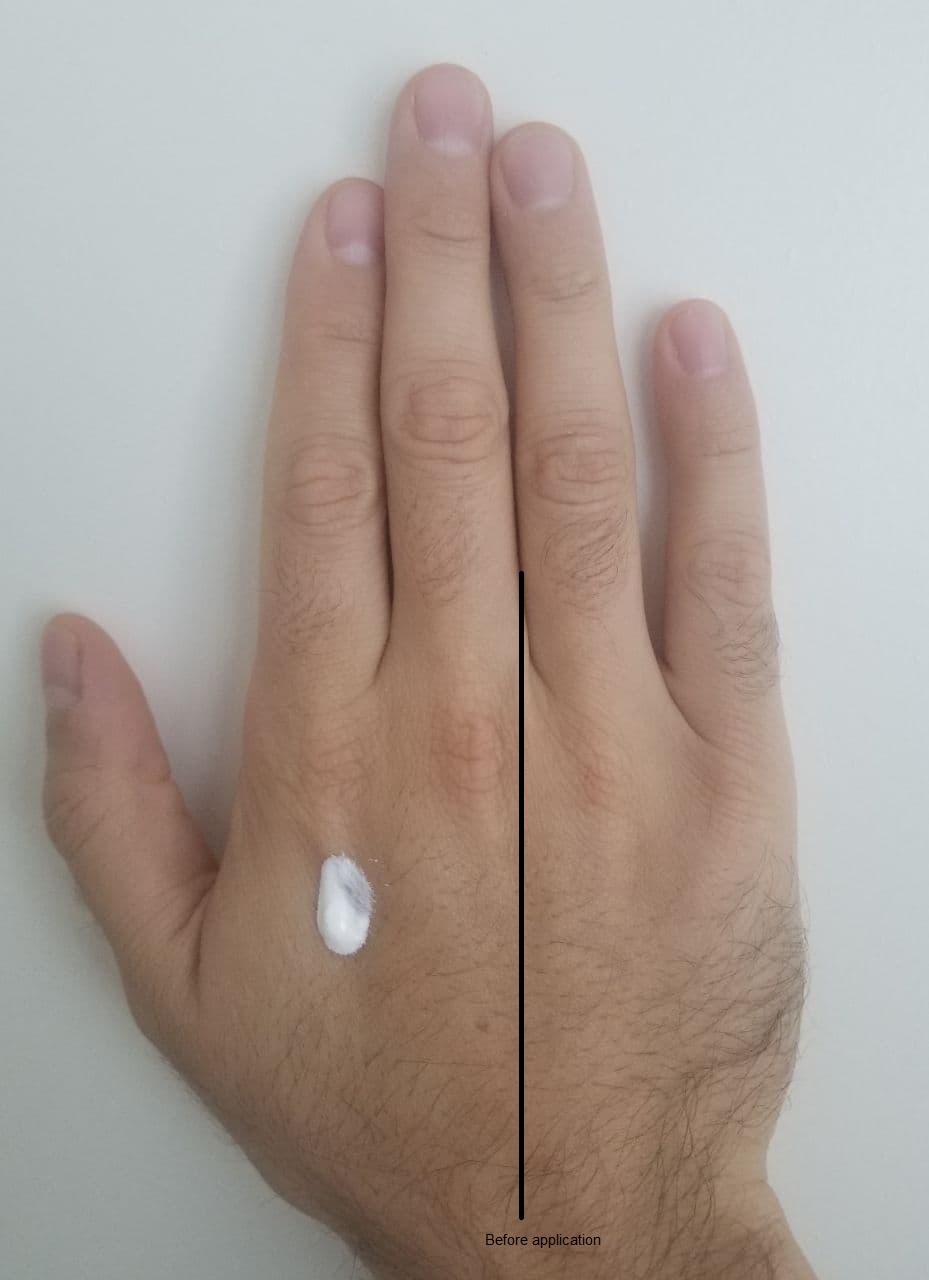

Thanks to the advancement in technology, a broad range of Non-nano TiO2 grades are now available and ZnO has also progressed from being just a UVA filter. Advances in ZnO particle size and shape technology has reduced the scattering of visible light and facilitated a high degree of transparency and efficacy even in Non-Nano sizes. Luxon KOREA with long time expertise in powder technology offers a wide range of TiO2 and ZnO that would make these type of formulations possible. We are pleased to share one novel formulation for a sunscreen and here with you, using only ZnO and having SPF 50+ and broad-spectrum PA+++ with amazing skin feel, pay off, and very minimal whitening. There were two different versions made, one with a better texture by using rotate mil for the dispersion.

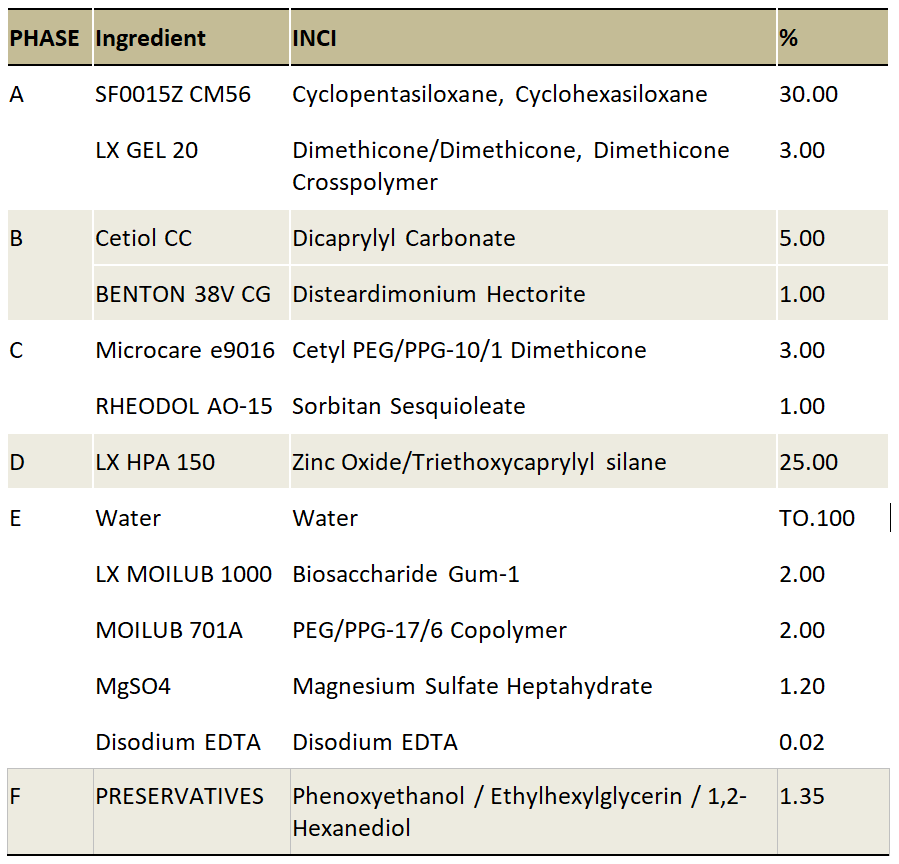

The first formula is a Mineral UV protection immediately, non-nano, and with moisturizing effect. There was only 25% of the innovative LX-HPA150 which is a Treated Zinc oxide with Triethoxy caprylly silane used

Non-nano mineral Sun Cream (SPF50+ PA++++)

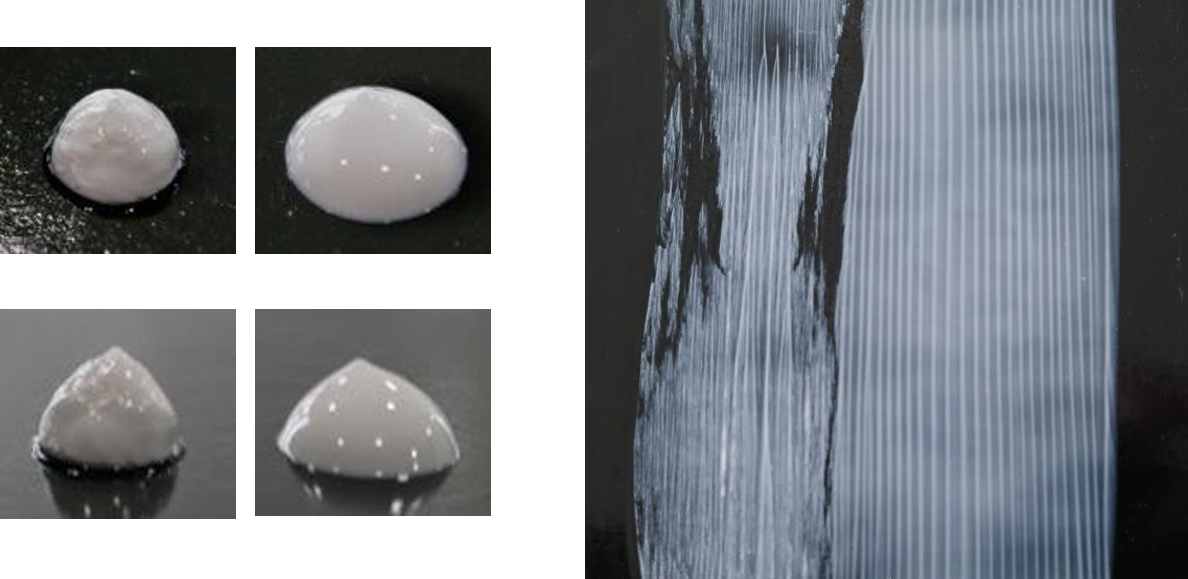

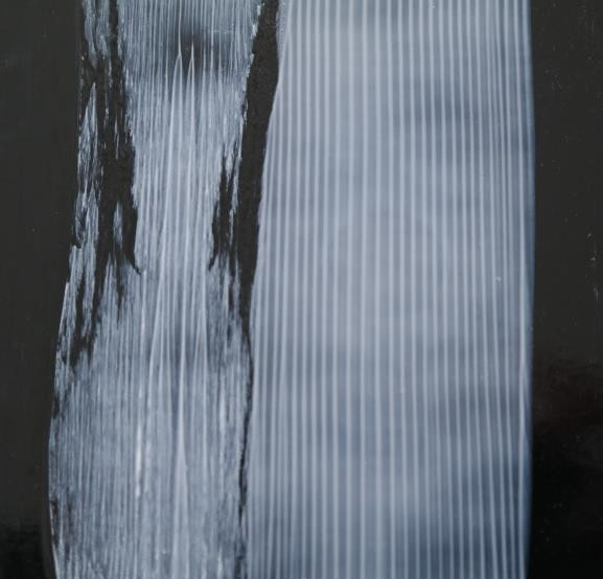

Advantage of Rotate Mill:

To have a better aesthetics, we also suggest using rotate mill for the dispersion. During normal dispersion, the powder is not evenly dispersed, and the below shape appears due to powder agglomeration. However, when dispersing with a rotate mill, the dispersion efficiency is higher than that of general dispersing, and the powder agglomeration phenomenon does not appear.

|

|

|

|

|

|

To know more about the above formulation and a full range of sunscreen and foundation formulations that we offer with novel sunscreen technologies from Luxon, please click here. (https://farachem.com/contact-us/)