Blog

November 8th, 2020

The causes of blooming in lipsticks and the solutions to avoid it

Introduction

Today lipsticks are most widely used to enhance the beauty of lips and to add glamour’s touch to the makeup to become more beautiful and more attractive. Modifying the formulation and the quality of lipsticks in recent decades accompanied by adding various advantageous ingredients leads to an increase in global demand for these kinds of products.

Then this high demand urges cosmetics producers to allocate a place on their product lists to a range of lipsticks.

As consumers have become more health conscious in recent years, the trend within the industry was to replace chemical ingredients with natural ones. In fact, lipsticks experienced quite the same trend. By this I mean, as lipsticks are in direct contact with one of the most sensitive parts of the body, say lips, and there is a possibility of their ingestion, consumers prefer natural ingredients.

Substituting some chemical ingredients with natural alternatives may produce different problems during the production, storage, handling, and application of newly formulated lipsticks due to their dissimilar nature. Beside the proper fluctuations in different batches, which are prevalent in formulating with natural ingredients, other important problems might also take place. Blooming or sweating, known as the appearance of oil droplets at the surface of lipsticks, is indeed one of the most important problems which could make the products undesirable and inapplicable in most cases of occurrence (Fig. 1).

Figure 1- Blooming of a lipstick

Solutions for prevention and fixation of the blooming problem

As blooming mostly noticed by consumers at the time of opening the products and in early stages of products usage it should checked accurately and solved immediately by producers if observed.

To overcome the blooming problem, cosmetic chemists must have a broad knowledge of lipstick ingredients, mainly newly added natural ingredients which requested by the marketing section to be incorporated into recently produced lipsticks. Being acquainted with the production methods of lipsticks and modifying the production stages and conditions might also be helpful in halting a lipstick from blooming or sweating.

Lipstick ingredients

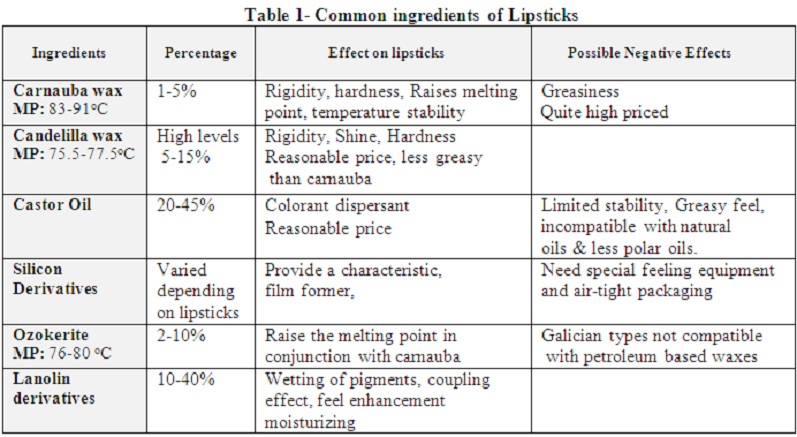

A lipstick is mainly composed of six basic materials, excluding colorants, preservatives, and perfumes (table 1) (1).

Other ingredients are normally added to lipsticks to enhance their structure and to create a better after-feel of application. For instance, Ceresin wax up to 15% enhances the de-moulding process and Fatty acid esters reduce the needed amount of castor oil. Hard butters, higher alcohols, synthetic waxes, vegetable oils, polymers are other examples which are worthy of mentioning.

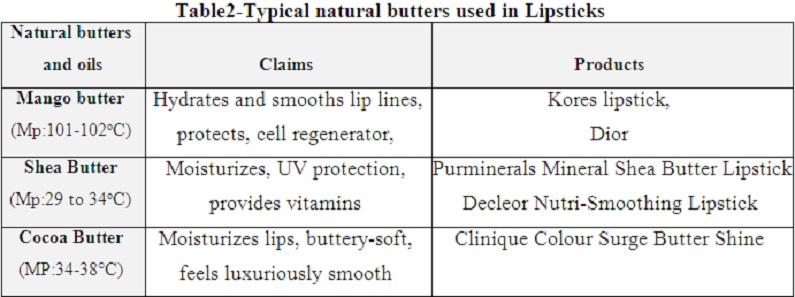

Ingredients which may cause lipsticks to bloom

Among all ingredients presented in lipsticks, as the recent blooming problem appeared after the addition of natural butters, first we have to investigate the hard butters and vegetable oils, which are characterized by containing high lauric triglycerides. In fact, these butters could trigger blooming by affecting the wax and oil structure of lipsticks. Typical natural butters which are used abundantly in products and their relating claims could be seen in the table below (table 2).

Choosing proper ratios of compatible waxes and oils in a lipstick formula normally results in stable and desirable products. However, addition of butters to the formula will change the ratio which normally consists of 75% oil and 25% wax and this may affect the wax lattice by weakening the binding forces between oils and waxes. As a result, the oil underneath could move up to the surface of lipstick and could cause blooming.

Research shows in case of adding Shea butter, the triglyceride composition is such that to obtain a good crystallization and stable crystals, a tempering process needs to be applied to the product. This tempering or pre-crystallization process brings the triglycerides into a stable crystal form and facilitates the crystallization when cooling the product. This cumbersome process can be eliminated by using hydrogenated Shea butters which have simpler crystallization behaviour. Poor crystallization can lead to oil migration and blooming (3).

Another study confirmed the worsening of affected crystalline lattice due to temperature fluctuations. In elevated temperatures the wax lattice modifies, and the wax-castor oil equilibrium altered resulting to the migration of castor oil due to incapability of lattice to hold the oil (4). Other studies suggested that the oil in wax/oil matrix was excluded with increasing temperature by expansion of volume through a channel within a lipstick (5).

Blooming may also occur in overheating butters like cocoa butter which could convert their structure to a less stable form. Indeed, bloom appears through the uncontrolled polymorphic transformation of cocoa butter from a less stable form to the most stable form. Overheating Shea butter and mango butter could also form fat granules or crystals.

Control the blooming caused by the alteration of wax/oil matrix:

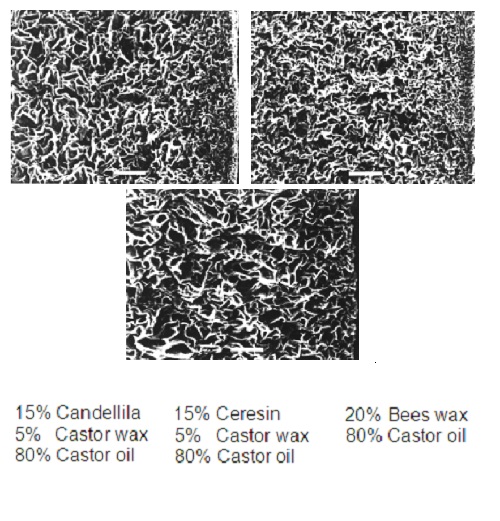

The modification of wax lattice by adding branch chain waxes will sterically hinder the straight chain waxes of formula. Incorporating more candelilla will increase the size of wax matrix because of its better compatibility with castor oil in comparison to ceresin and beeswax. (Fig. 2) (6).

Figure 2- Candelilla’s effect on wax matrix

Besides decreasing the percentage of straight chain waxes such as microcrystalline waxes, the inclusion of heavy branch chain waxes (C18-C32), triglycerides of fatty acids and ethylene glycol esters of fatty acids in combination with branched chain oils would make the matrix such modified that no realignment could take place.

Other causes of blooming and their solutions:

1-Moulding, moulding temperatures and temperature fluctuations:

Outer part of lipsticks undergoes significant stress at the time of contacting the moulds and accompanied by the changes in their crystal lattice. In case of moulding temperature a research showed that increasing the moulding temperature to near 50°C will expand its matrix size and consequently will reduce the probability of lipsticks’ sweating in great amounts (6). Moreover temperature fluctuations specially temperature increase in a short time, mainly in summer, results in modification of wax/ castor oil matrix and promotes the migration of castor oil to the surface of lipsticks which ends to blooming (4). Most of these problems could be minimized by strengthening the wax/oil matrix and improving lipsticks’ lattice which discussed before.

2-Flaming and silicone spraying:

Studies showed that flaming of lipsticks for improving their surface appearances may cause sweating in some cases, but if performed properly, might delay sweating by augmenting the wax/oil matrix. Flaming causes the top surface of the stick to melt and consequently the bigger rearrangement in the wax/oil matrix of the melted part take place due to slow cooling in room temperature. In addition, using post-moulding sprays of silicone is widespread in Europe to obtain lipsticks with shiny surfaces but excessive spraying of silicones can cause mottled surfaces and blooming over time (7).

3-Delay times and cooling rates:

Negative effects caused by delays could be omitted when lipsticks benefit from a strength and cohered wax/oil structure. Delays which should be considered between moulding, flaming and testing a lipstick play a role in blooming. Experiments showed that sweating reduces by considering a delay between moulding and flaming. On the other hand, immediate testing of the products after flaming showed little or no bloom in conducted tests comparing to products left 24 hours after flaming. These all appear because of their effects on the formation of lipstick’s surface and inside matrixes. Slow controlled cooling of products at unrealistic rates will also achieved to a grainy stick likely to sweat (6).

4-Pigments, colour concentrates, dry pearls and lanolin addition:

Pigments, mostly including near 5% of lipstick formula, could influence the product stability by weakening the binding forces between oil and waxes. While pigments should disperse in 50% of the total castor oil presented in lipsticks, they inhibit the castor oil from becoming well associated with the wax base and cause the lipstick to become soft. Adding titanium coated mica type pearls which could act as sponge for unbounded castor oils could inhibit oil migration and might help halting products from blooming. Moreover, some derivatives of lanolin could help minimising the sweating and cracking of sticks (8).

5-Incorporating gelling agents to the formula:

High levels of glycerin in lipsticks increase the risk of blooming occurrence because glycerine’s affinity to attract water from surrounding atmosphere leads to the displacement of attracted water with some portions of the oils presented in lipsticks’ matrixes. Gelling agents, when incorporating to the formula, combine with the oils and help their retention in the formula even under high humidity and temperature. The addition of emulsifiers as gelling agents might also be helpful to bind the oils and keep them from coming out (9).

Conclusion

All in all, blooming can easily ruin lipsticks when over or under processed due to its negative effects on products feature, quality and ease of its application. Accordingly, the quality control and R&D chemists must pay special attention to this problem in order to make lipsticks acceptable in their intended markets. Considering the mentioned factors and causes, especially the ones which directly affect the lipstick’s wax/oil matrix such as incorporation of natural butters, modification of the waxes and oils and pigment loading for enhancing their colour, should be investigated wisely during production. Besides, taking notice of other factors including production methods, processing temperatures, moulding, flaming and packaging procedures would also be helpful in preventing products from blooming.

References:

1- Schlossman.M.L, Finkenaur.G, The chemistry and manufacture of cosmetics vol.3 Book 3, chapter 22, Lipsticks p. 629-657,

2- Peevers. R. et al., January 2009. Creating enhanced Lipsticks formulations, Personal care, p. 43, Croda consumer care Europe.

3- Alander.J, Andersson.A, The shea butter family, the complete emollient range for skin care formulations. Karlshamns AB, Lipids for Care, 37482 Karlshamn, Sweden

4- Dweck A.C., The sweating of lipsticks, cosmetic & toiletries 29:96 January 1981.

5- Matsuda H. et al., J. Japan Soc. Color Material, 57:130(1984)

6- Seo S. Et al., Observation the sweating in lipstick by scanning electron microscopy, IFSCC congress Sydney Australia 1996.

7- Geoffrey Finkenaur, The chemistry and manufacture of cosmetics chapter 22, Lipsticks p. 629-657,

8- Sitaram Dixit, Lanolin for silky, soft and smooth skin, Chemical weekly, October 30, 2010.

9- David et al. Non-sweating lipsticks, The P&G company. 1995. USP 94/11510.